State Acceptance Commission ('Gospriyomka') in the USSR

§ Introduction of State Acceptance Commission in the USSR - 1986

§ State Acceptance Commission and 'Uskorenie' (Acceleration)

§ State Acceptance Commission's Mark

§ Background

In January 1985 (before the arrival of M.S. Gorbachev to power), The Soviet Commission for Standardization (Gosstandart) instructed its representatives to visit several enterprises in the engineering industry to assess the quality of production at all stages, including development.1

In a market economy, product assessment is driven by consumer response - if a product deteriorates, consumers will stop purchasing it. In this context, the "fault" of the producer can result from not only poor product quality but also lagging behind competitors.

In a socialist economy, where the consumer lacks free choice, the situation is somewhat different. While there may formally be several types of soda, TV models, and so on, they are produced in enterprises with approximately the same level of management, leading to minimal differentiation. Even if the quality of such products leaves much to be desired, consumers cannot choose anything else as there is no fundamental competition.

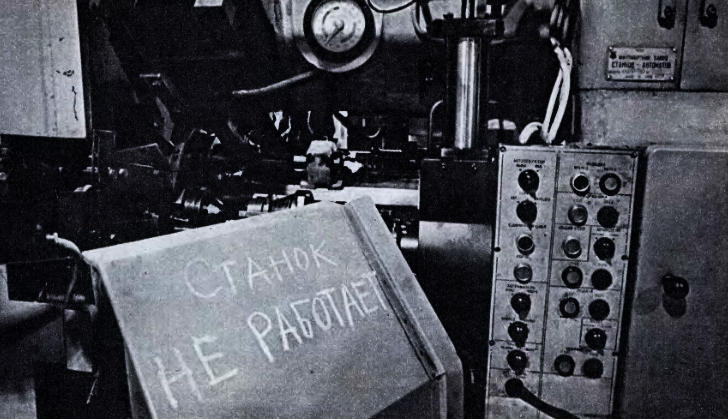

This is why in the planned Soviet economy, the role of quality controller was supposed to be assumed by government commissions, rather than consumers. By the mid-1980s, the situation with the quality of Soviet goods, even according to official data, was not optimal. A certain marker for assessing all produced goods was warranty repairs, i.e., cases where purchased equipment needed repair due to various malfunctions..

For example, the brochure "State Acceptance Commission ('Gospriyomka')- An Effective Lever for Restructuring" reports that in 1985, Soviet consumers returned "Horizon" televisions to stores 48% more than in the previous year of 1984, "Quartz" televisions nearly a third more, "Emerald" televisions 59% more, and "Sadko" televisions more than 80% more. This indicated a growing incidence of "defective production".

Several times in USSR history some attempts were made to reduce the amount of defective products. Certainly, by the time State Acceptance Commission was introduced, there was a quality control department - the Technical Control Department (TCD) - in the production facilities. However, as was evident from the warranty repair statistics, this Department was not fulfilling its duties. In order for quality control to be independent of the enterprise directors, it was decided to introduce an additional supervisory body whose members were not associated with the enterprise and, accordingly, were not dependent on the management of the enterprise.

Introduction of State Acceptance Commission in the USSR - 1986

The introduction of State Acceptance Commission ('Gospriyomka'), like almost any Soviet innovation during the era of Perestroika, was regulated by the corresponding resolution of the Central Committee of the Communist Party of the Soviet Union (CPSU).

In the resolution of the CPSU Central Committee dated May 12, 1986, "On measures for a fundamental improvement in the quality of products," it was stated that starting from January 1, 1987, State Acceptance Commission would be introduced "in associations and at enterprises producing essential economic products, consumer goods, as well as major component parts and materials for them."

Also, this resolution indicated that this body was established for "a fundamental improvement in the quality of manufactured products, acceptance of finished products, and control of the activities of associations and enterprises in quality matters." Therefore, the remaining part of 1986 year was to be allocated for necessary preparatory activities. Hence, the actual implementation of State Acceptance Commission should be considered as January 1, 1987.

Additionally, the document mentioned that there were control departments that were "not staffed with qualified personnel and did not have modern control tools." Consequently, the essence of State Acceptance Commissions was to create a new quality control barrier staffed with qualified specialists, and directly independent of the enterprise they were overseeing.

Soviet brochure with the headline 'State Acceptance Commission - is an Effective Lever of Perestroika'

Organizationally, the State Acceptance Commissions were subordinate to the State Committee of the USSR for Standards, which is logical. It was implied that only highly qualified specialists would be included in such commissions. As for the leaders of the newly established commissions, they were selected from the ranks of chief engineers, chief designers, and other similar executive positions. Thus, we can speak about the organizational establishment of the system of State Acceptance bodies in 1986, while the actual implementation in the production facilities can be traced back to January 1, 1987.

It should be noted immediately that the new supervisory commission did not cover all enterprises in the country. For example, in 1987, only 20% of the total industrial production of the country was subject to inspection. Furthermore, of the verified output, 60% comprised production from the engineering sector, while 40% was from metallurgy, chemistry, and petrochemistry.2 Additionally, in 1988, the scope of the new acceptance was expanded to include processing plants in the agro-industrial complex, as well as residential construction and facilities of socio-cultural significance.

Announcement on the Expansion of the Scope of State Acceptance Commission (1987, Soviet Television Broadcast)

§ Principles of Control

What were the main principles of State Acceptance Commission control? What were the specific tasks of the established commissions? Let's refer to the official testimonies of those years. The brochure "State Acceptance Commission - Striving for Quality" defined this scope of competence:

☛ Quality control of products at any stage of production;

☛ Selective inspection of any items;

☛ Final acceptance of fully equipped products;3

As for the actual duties of the State Acceptance Commission members, they can be summarized as follows:

☛ Quality control of technological processes, components, semi-finished products, materials, and raw materials;

☛ Monitoring the timely implementation and adherence to standards

☛ Inspection of measuring instruments;

☛ Monitoring the implementation of government decisions related to improving product quality;;

☛ Collaborative analysis with the enterprise manager of complaints received from consumers;

☛ Verification of technical documentation.4

§ State Acceptance Commission and 'Uskorenie' (Acceleration)

Conceptually, the State Acceptance Commission was tied to the concept of "Uskorenie" (Acceleration). In the brochure "State Acceptance Commission Examines," it is mentioned that during one of the meetings, Gorbachev directly linked the concept of "Uskorenie" (Acceleration) with the quality of the manufactured products: "Speaking about the necessity of accelerating the socio-economic development of the country, the General Secretary emphasized that "Uskorenie" (Acceleration) should only happen through high quality, through better products with greater productivity, enabling the implementation of labor-saving, resource-saving technologies, and so on <...> "Uskorenie" (Acceleration) is inseparably linked to quality. Those who think otherwise simply do not understand what "Uskorenie" truly is." 5

§ Results

The State Acceptance Commission system did not have significant global consequences and could not fundamentally change the quality of the manufactured products. To a certain extent, this was due to the so-called "human factor," whereby State Acceptance Commission members became influenced by the interests of the enterprises. This did not occur immediately but gradually.

Secondly, the new system did not provide any incentives for improvement, meaning that employees simply lacked material motivation to strive for betterment. Everything was carried out within the framework of disciplinary measures.

Finally, the third important factor was that even a qualified State Acceptance Commission member could not assess all the properties of a product. For example, the degree of equipment wear and tear was not always immediately apparent and required a certain period of use to determine whether the product had performed well or not.

Moreover, the new quality control system was not universal. As mentioned earlier, in 1987, the new control covered only 20% of the total industrial production. This meant that attention was not focused on all the products being manufactured.

In essence, State Acceptance Commission became a duplicate of the Technical Control Department. However, even the combined efforts of these two organizations could not replace the main quality criterion: consumer trust.

§ State Acceptance Commission's Mark

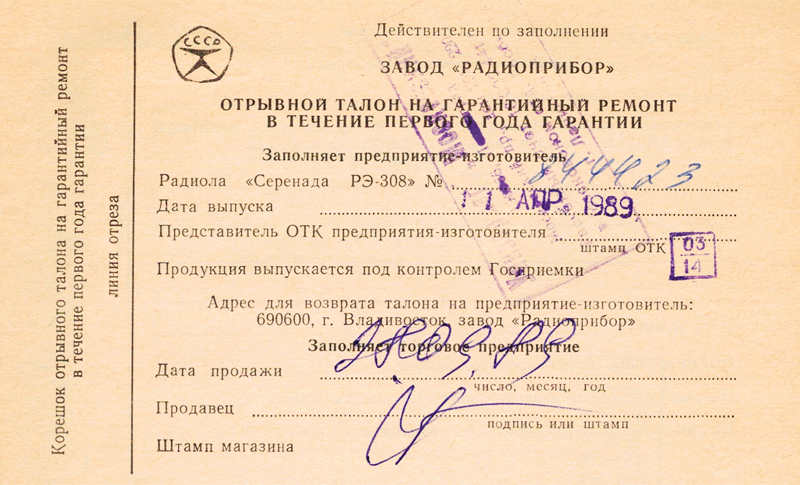

Marks of control by the State Acceptance Commission could be found in the accompanying documents for the product, specifically in the warranty certificate, which is logical as it directly relates to quality issues. For example, a warranty certificate from 1989 with the mark "The product is manufactured under the supervision of State Acceptance Commission"

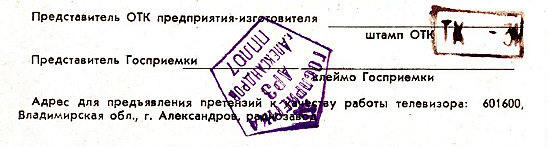

There were also stamps or Gospriyomka's marks that could be used to indicate checked products. In the warranty certificate, a special line could be highlighted, titled "State Acceptance stamp," where this stamp would be placed accordingly.

_____

1, 5 Belyaev V.S. "Gospriyomka Examines," Moscow Worker, 1988, pp. 3, 15

2 Omelyanchik V.I. "Gospriyomka: A New Level of Quality," State Committee on Science and Technology of the USSR, Moscow, 1988, p. 13

3, 4 Agishev Yu.V. "Gospriyomka - the Struggle for Quality," Society "Knowledge," RSFSR, Krasnodar Regional Organization, 1988, pp. 18-19